Bulker Automation

Product Overview

The AI-Based Bulker Chute Automation System by Amazin Automation is

a next-generation smart loading solution designed to automate and optimize

the bulk cement loading process.

In traditional cement plants, loading bulkers manually leads to inaccuracies,

delays, material spillage, and safety risks. This AI-driven system

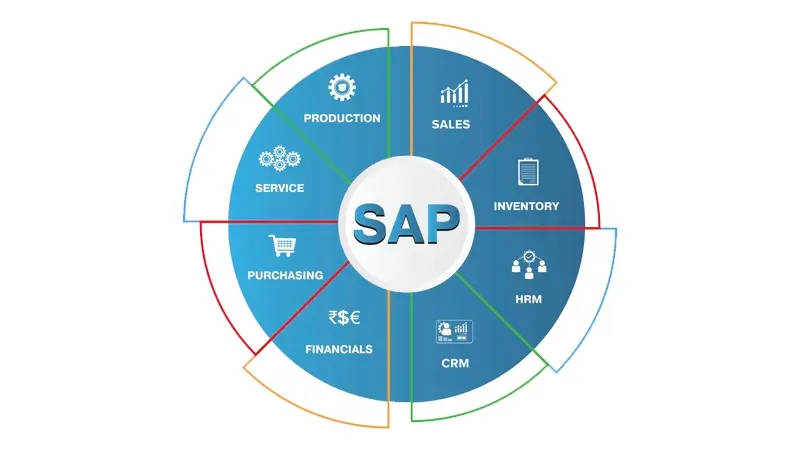

revolutionizes the process by integrating computer vision, ANPR

(Automatic Number Plate Recognition), SAP/ERP synchronization, and

real-time monitoring, creating a completely hands-free, intelligent, and

error-free loading operation.

It eliminates the dependence on human judgment, enhances operational

transparency, ensures regulatory compliance, and guarantees accurate,

safe, and efficient cement loading—significantly improving productivity

across cement plants and dispatch operations.

Product Overview

Automation of Bulker Loading Operations:

Minimize manual intervention and human errors during chute positioning and loading.

Precision in Chute Positioning

Use AI-based visual intelligence to confirm exact alignment of chute and bulker inlet before starting the load.

Vehicle Validation and Security

Verify bulker identity using ANPR technology and cross-check against authorized SAP records.

Seamless SAP Integration

Real-time synchronization of trip data, vehicle info, material details, and weight records.

Safety and Supervision

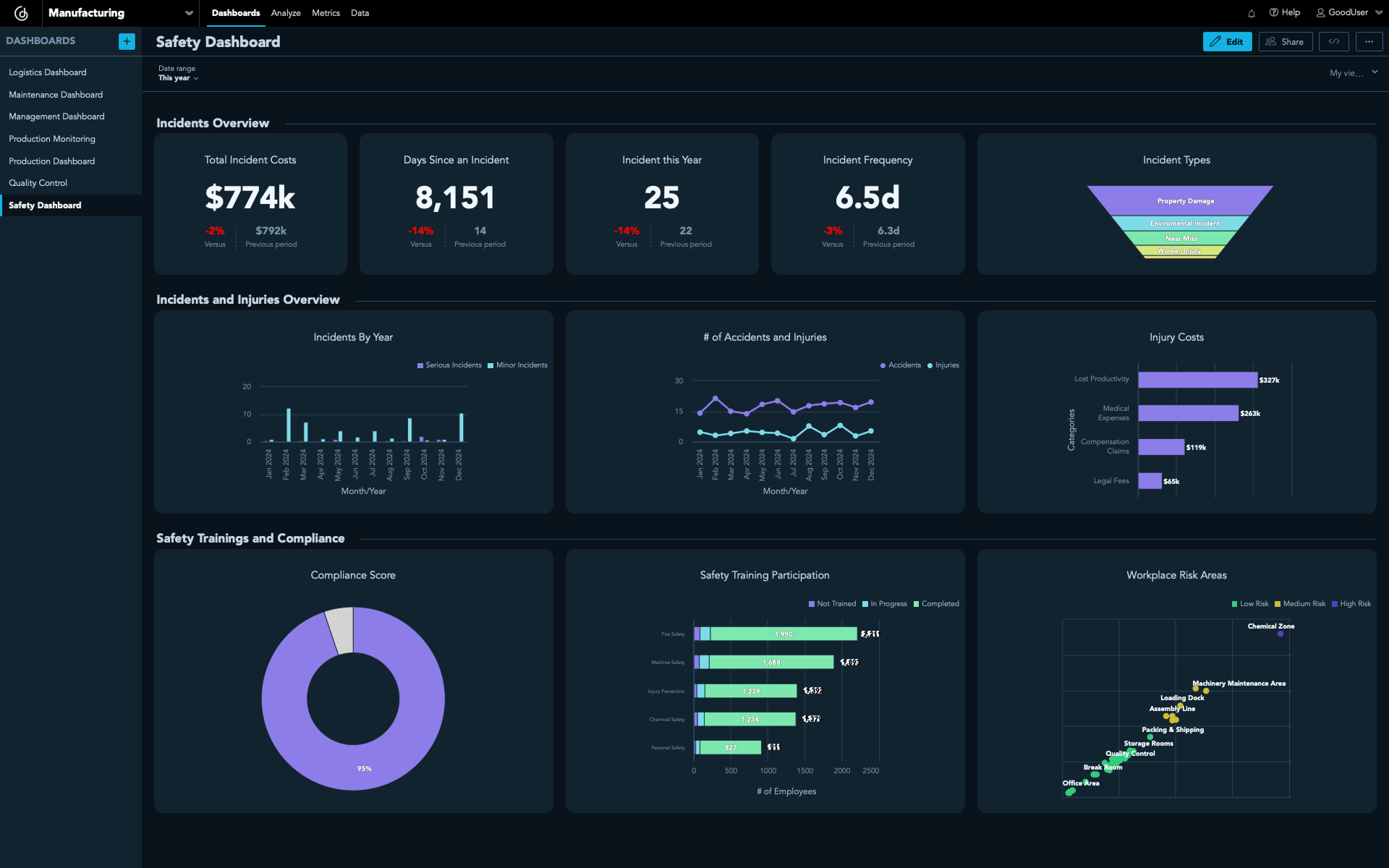

Provide operators with a live monitoring dashboard to oversee each step of the loading operation.

Data Transparency and Traceability:

Auto-generate digital records for every trip for audit and analysis.

Key Features

AI-Powered Chute Position Detection

- Prevents cement spillage and contamination by ensuring proper alignment before material flow begins.

- Sends automated confirmation signals to initiate loading only when alignment is verified.

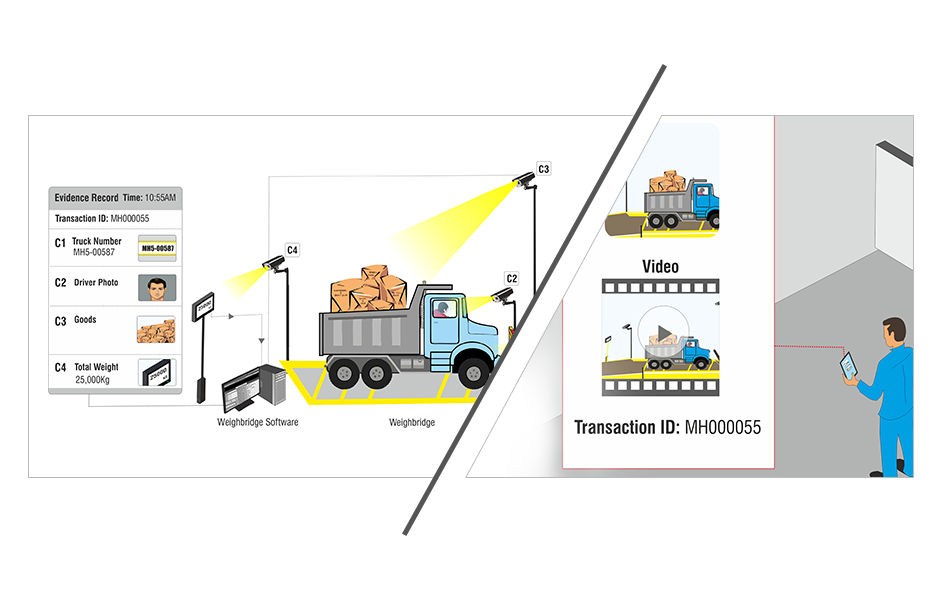

Automatic Number Plate Recognition (ANPR)

- Captures, reads, and verifies truck registration plates

- Matches captured data with the pre-approved trip details stored in SAP or internal databases.

- Prevents unauthorized or wrong vehicle loading, ensuring safety and accountability.

Real-Time Camera Monitoring

- Multiple IP cameras provide live video feeds of chute alignment, material flow, and bulker positioning.

- Operators can monitor the full process remotely through the central dashboard.

- Enables instant corrective action if any deviation or error occurs.

SAP / ERP Integration

- Bidirectional data exchange between the Bulker Chute Automation System and SAP ERP.

- Automatically updates trip details, material weights, and dispatch completion data.

- Eliminates manual data entry and minimizes clerical errors.

Automated Trip and Loading Log

Each trip is automatically logged with the following parameters:

- Vehicle Number

- IGP (Inbound Goods Permit) Number

- Tare & Gross Weight

- Material Type and Quantity

- Order / Dispatch Number

- Date & Time Stamp

All logs are stored digitally for future audit, traceability, and reporting.

Applications

- Cement Plants: Automates and streamlines bulk cement dispatch operations.

- Logistics Terminals: Ensures authorized dispatch and reduces loading time.

- Ready-Mix Concrete (RMC) Plants: Guarantees precision in cement loading for batching.

- Manufacturing Units: Improves operational accuracy and eliminates manual dependency.

- ERP-Based Supply Chains: Offers a complete digital trace of every bulker trip.

Benefits

Operational Efficiency

- Reduces loading cycle time and manual effort.

- Enhances throughput and minimizes downtime between dispatches.

Accuracy & Compliance

- Assures precise weighing, material quantity verification, and regulatory

compliance. - Minimizes risk of incorrect loading or overloading.

Enhanced Safety

- Eliminates human involvement in high-risk loading areas.

- Prevents accidents due to chute misalignment or vehicle mismatch.

Real-Time Supervision

- Operators can view the entire loading sequence live via camera feed

and system dashboard. - Facilitates proactive intervention in case of anomalies.

Data Transparency

- Centralized digital record-keeping of each transaction.

- Enables analytics for performance tracking, maintenance scheduling,

and quality control.

Cost Optimization

- Reduces cement wastage, prevents overloading penalties, and optimizes manpower utilization.

- Ensures better ROI through improved resource allocation.

System Dashboard and Monitoring

- Operator Interface: Real-time visualization of chute status, vehicle info, and loading progress.

- Live Feed Integration: On-screen camera monitoring of chute and bulker alignment.

- Automated Alerts: System-generated alerts for misalignment, unauthorized vehicles, or process errors.

- Audit Logs: Complete transaction history available for compliance and analytics.

Technical Integration

- The system seamlessly integrates:

- AI Cameras (for vision-based chute detection)

- ANPR Cameras (for vehicle identification)

- PLC and Sensor Modules (for automation control)

- Weighbridge Interface

- SAP / ERP Data Exchange API

Summary

- The AI-Based Bulker Chute Automation System is a smart, scalable, and future-ready solution for bulk material dispatch operations. It combines AI, automation, and ERP connectivity to deliver:

- Faster operations

- Zero spillage

- 100% loading accuracy

- Secure, authorized vehicle access

- Full operational visibility

- It redefines how bulk loading is executed—making plants more efficient, compliant, and digitally empowered.